Keeping You In Control.

Automation Controls Maintenance, Support & Project Services

At Industrial Control Repairs (ICR), we understand that downtime is more than an inconvenience, it impacts productivity, safety, and profitability. That’s why we provide specialized industrial maintenance and support services designed to keep your control systems operational, efficient, and compliant.

We provide full, turn-key project services, managing the entire project life cycle, including scope development, justification, design, development, implementation, startup, training and support. Our approach is rooted in preventive maintenance, system documentation, and fast, reliable response. Whether you’re managing legacy systems or modern industrial automation, ICR offers the field expertise and technical knowledge to ensure everything runs smoothly.

Protecting Uptime with Expert Control System Support

ICR provides immediate comprehensive service to facilities throughout Northeast Florida and Southeast Georgia, including manufacturing plants, dredge controls, material handling systems, and industrial automation environments.

ICR's maintenance & support services:

Scheduled Preventive Maintenance

Regular service visits tailored to your system’s needs — minimizing the risk of unexpected failures and extending equipment life.

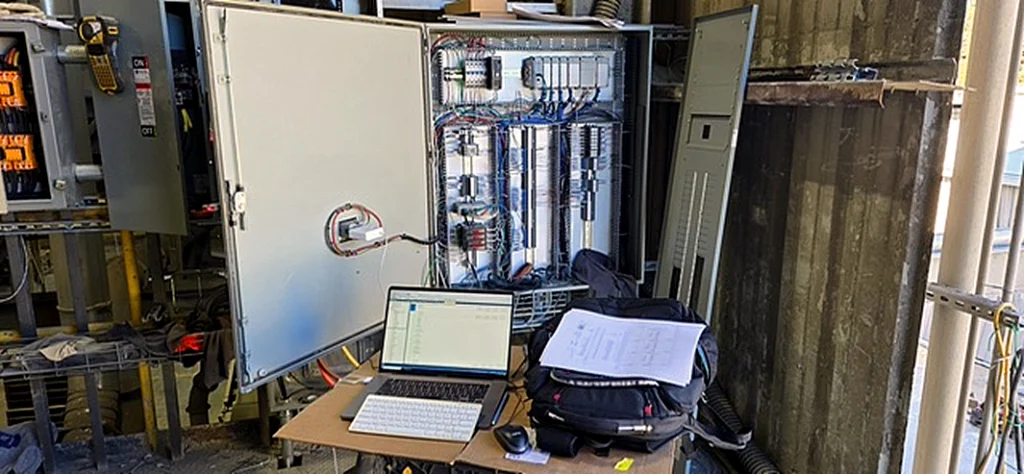

On-Site Control SYSTEM Modifications

Adjustments, retrofits, or component upgrades to your existing field equipment, helping you adapt without overhauling entire systems.

Electrical Wiring Diagram Review & Update

On-site verification and updates of your electrical control wiring diagrams to maintain accuracy and support troubleshooting efforts.

PLC Code Version Control

Maintain and track versions of your PLC logic to prevent loss, confusion, or downtime caused by undocumented changes.

PLC and HMI Program Backups

Upload, backup, and secure your existing programmable logic controller (PLC) and human-machine interface (HMI) programs for disaster recovery and change management.

VFD Parameter & Transmitter Scale Factor Documentation

Record and store critical settings for variable frequency drives (VFDs) and process transmitters, ensuring faster recovery after equipment replacement or reprogramming.

Component Verification & Obsolescence Checks

Identify outdated hardware, missing documentation, or unsupported devices before they become a problem, allowing for smart replacement planning.

Hands-On Expertise.

Proven Results.

-

Minimize Downtime, Maximize Efficiency

Proactive strategies to reduce interruptions and keep your operations running at peak performance. -

Preventive Maintenance & Calibration

Scheduled service trips and precise sensor calibration to prevent issues before they occur. -

Expert On-Site System Updates

Hands-on verification of control wiring, code updates, and field panel modifications. -

Complete System Backup & Documentation

Backups of PLC and HMI software, version control, and critical data like VFD parameters and transmitter scale factors. -

Data-Driven Performance Insights

Integrated logging and reporting tools to support maintenance planning and operational analysis. -

Industry-Wide Service Integration

Maintenance and support aligned with your full system lifecycle—from automation to field operations. -

Scalable Remote Support & Monitoring

Advanced remote diagnostics to monitor and assist systems across any location.

Local, Field-Tested, and Ready to Respond

Based in Northeast Florida, ICR proudly serves facilities across Jacksonville, St. Augustine, Palatka, Gainesville, and into Southeast Georgia. With a strong understanding of local industry needs, and no layers of overhead, you get fast, focused support from someone who knows your equipment and environment. For our nationwide clients, ICR extends the same responsive, expert-level support to multi-location facilities across the U.S., ensuring consistent uptime and operational reliability at every site.

We have been designing, implementing and supporting process and manufacturing automation systems for 45 years. We support dredging, aggregate, cement, food & beverage, chemical, warehousing and manufacturing industries.

The Cost of Ignoring Maintenance

Too often, industrial facilities take a reactive approach to automation failures by addressing issues only after systems go offline. Industrial Control Repairs takes a proactive, technician-led approach that prioritizes system health, safety, and preparedness.

ICR support visits help you:

- Avoid unexpected/long-term shutdowns

- Maintain compliance with safety and quality standards

- Protect critical programs and settings

- Ensure system documentation stays accurate and up to date

- Gain peace of mind knowing you’re supported by a local expert

Keeping You in Control.

Whether you need a one-time system check, ongoing preventive maintenance, or guaranteed emergency support, Industrial Control Repairs is ready to help. Let’s make downtime a thing of the past.